Smart Manufacturing Solutions

Smart Manufacturing Solutions for the Industry 4.0 Era

The revolution in manufacturing is reshaping the industries. Manufacturers face unprecedented demands for efficiency, precision, and scalability. Our advanced automation systems are at the forefront of this transformation, leading the charge in cutting-edge technologies that empower industrial manufacturers to stay ahead of the curve.

Trusted by the world’s top automotive manufacturers, leading the manufacturing industry. Our solutions for Body-in-White (BIW) shops have redefined the standards for operational efficiency, data integration, and production intelligence.

Seamless Integration with Existing Infrastructure: We build upon your current systems, maximizing the potential of your existing PLC infrastructure with minimal disruption.

Our Vision for Manufacturing Excellence

A Commitment to Innovation Manufacturing

We are dedicated to driving innovation across every phase of the manufacturing process, from assembly line automation to data-driven decision-making.

Sustainability and Efficiency Production

Our solutions not only about how to enhance manufacturing productivity but also prioritize energy efficiency and sustainability, helping manufacturers reduce their environmental footprint while increasing output.

Tailored Solutions for Every Manufacturer

Our automation systems are fully customizable to meet the unique needs of each manufacturer, ensuring seamless scalability and flexibility in production.

Core Features of Our Advanced Automation System

Comprehensive Automation System

Our platform combines sophisticated data collection, organization, analysis, and reporting tools with the operational capabilities of existing PLCs to streamline manufacturing operations. By utilizing your existing infrastructure, we ensure seamless data integration and enhanced production intelligence.

Data Logging and Integration

Centralized Data Logging: Data from your PLCs is securely stored in a robust database server, ensuring reliable, real-time storage.

Seamless Integration: We integrate additional equipment, such as welders, sealers, and other key machinery, creating a unified and cohesive system that connects every part of your production line.

Unified Data Source: This centralized data provides a single, consistent source of truth for all operations, making it easier to monitor and optimize every step in the process.

Data Organization and Analysis

Structured and Actionable Insights: Data is organized into easy-to-understand formats, ready for in-depth analysis and real-time decision-making. These insights directly influence process optimization and operational improvements.

Centralized SCADA Visualization

Intuitive Control for Operators: Our centralized SCADA system offers real-time monitoring and management across the entire production line, giving operators the control they need to make quick decisions with confidence.

Unified Dashboard: Operators can monitor multiple lines and systems from a single, intuitive interface, streamlining operations and reducing manual intervention.

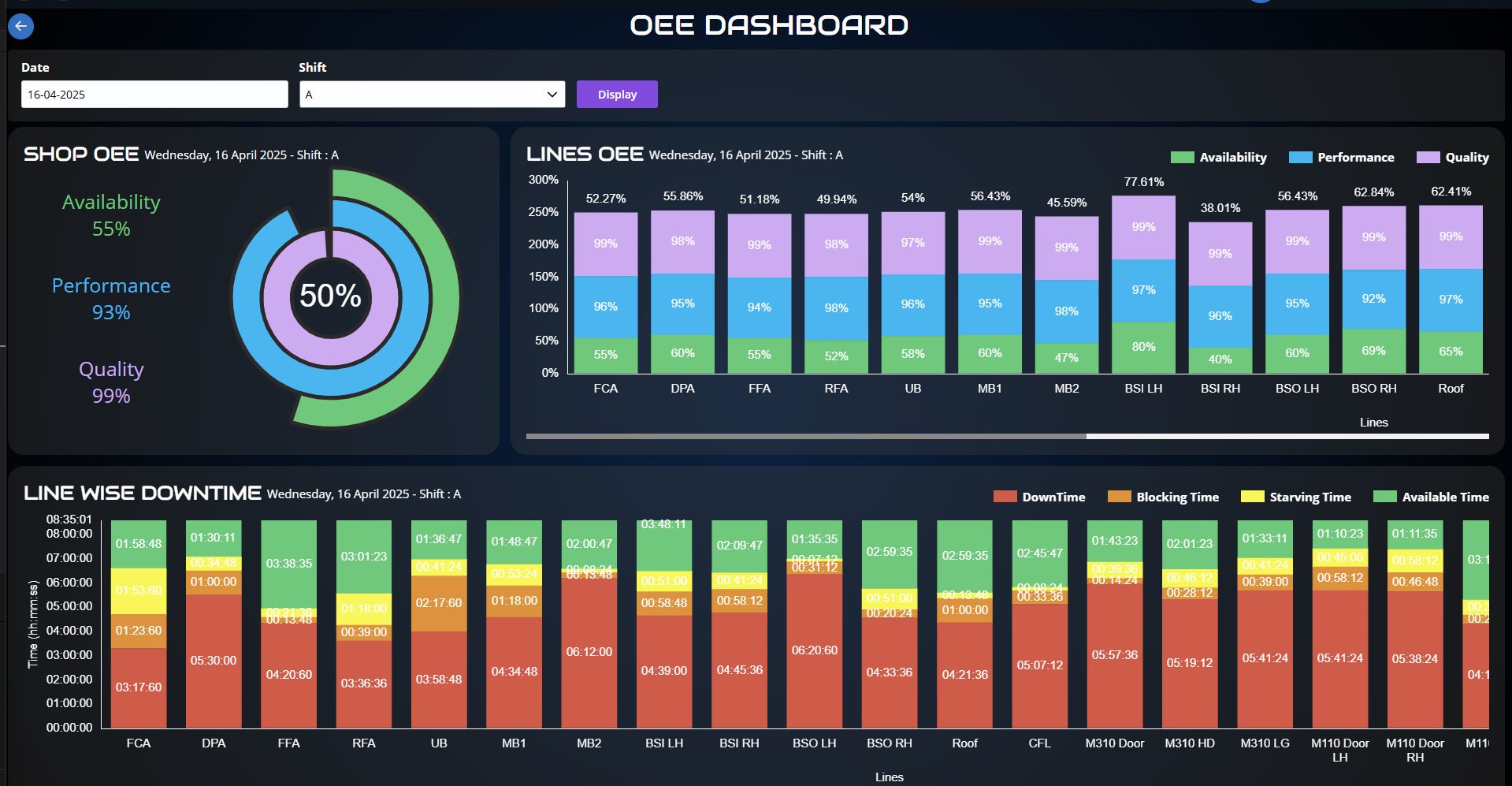

Advanced Dashboards and Reporting

Our interactive dashboards allow users to explore data with ease, drilling down into detailed metrics for a deeper understanding of their operations. Comprehensive reports provide actionable insights that drive continuous improvement in manufacturing process.

Real-Time Visualization: Key performance indicators (KPIs) and critical metrics are displayed in an accessible and visually appealing format, empowering operators to react swiftly to production needs.

Comprehensive Reporting: Leverage SQL Server Reporting Services (SSRS) to generate professional, customizable reports that can be previewed on-screen and exported to Word, Excel, or PDF for seamless sharing and archiving.

Large-Scale System Integration

Robotic Systems: Our advanced automation solutions ensure the flawless coordination of hundreds of robots, guaranteeing precision, consistency, and efficiency in your manufacturing process.

Sealers and Welders: Integration with sealers and welders ensures that all systems work in perfect harmony, optimizing performance and quality.

Imaging Devices: High-resolution cameras provide real-time quality control, identifying defects and ensuring every part meets rigorous standards.

Benefits for Manufacturers

Cost Savings & Faster Time-to-Market: Our automation solutions reduce manual labor, streamline production processes, and minimize operational costs, enabling faster delivery times without compromising on quality.

Worker Safety & Operational Risk Reduction: By automating dangerous or repetitive tasks, we help create a safer work environment, reducing injury risks and improving overall operational safety.

Maximized Productivity & Reduced Waste: With intelligent systems in place, industrial manufacturers can achieve higher production yields while significantly reducing waste and defects.

Seamless Scalability: As production demands grow, our systems can scale seamlessly to meet your evolving needs without requiring a complete overhaul.

Driving the Future of Manufacturing

Proven Success Across Industries

Our advanced automation systems have been successfully adopted by some of the leading automobile manufacturers worldwide, showcasing their scalability, reliability, and ability to meet the challenges of modern manufacturing environments.

Sustainability at the Core

Our automation solutions are designed with sustainability in mind, helping industrial manufacturers reduce energy consumption, emissions, and waste while increasing production efficiency.

Empowering Innovation

Our systems empower manufacturers to adopt the latest manufacturing technologies, positioning them as leaders in the competitive market.

Our Process

Consultation and Design

We begin with an in-depth consultation to understand your manufacturing needs, designing a tailored automation solution that integrates seamlessly into your production line.

Custom Implementation

Our expert engineers handle the complete implementation, ensuring minimal downtime and maximum efficiency.

Ongoing Support and Maintenance

We provide continuous support and system updates to keep your operations running smoothly and at peak performance.

Why Choose ENWPS?

Expertise in Manufacturing: With years of experience in the automation and robotics industry, we specialize in the nuances of different manufacturing and automation needs.

Innovation and Customization: Our solutions are built with flexibility in mind, ensuring they evolve with the growing demands of your business.

End-to-End Support: From initial consultation to ongoing system updates, we stand by your side, offering comprehensive, ongoing support.

Explore how our automation systems can streamline and elevate your automotive manufacturing processes. Contact us today!

FAQs

- 1. How do your automation systems integrate with existing PLC infrastructure?

- 2. Are your solutions customizable for EV manufacturing needs?

- 3. What is the typical implementation timeline for your automation system?

- 4. Is your automation system compatible with robotics and advanced manufacturing equipment?

- 5. What are the cost considerations for implementing your automation system?

- 6. Is your solution scalable for future production needs?

- 7. How can I schedule a consultation or demo?

Our systems are designed to seamlessly integrate with your existing PLC infrastructure by leveraging your current setup. We edit and enhance PLC programs as needed, ensuring smooth data collection, organization, and visualization without disrupting ongoing operations.

Yes, our automation systems are fully customizable. Whether you need tailored dashboards, reporting features, or integration with specific equipment like welders, sealers, or imaging devices, we design solutions that align perfectly with your production requirements

The timeline varies depending on the size and complexity of your production line, but we focus on minimizing downtime. Typically, a comprehensive implementation takes between 4 to 12 weeks, including system testing and staff training.

Absolutely. Our solutions integrate seamlessly with robotic systems, welders, sealers, and imaging devices, ensuring synchronized operations across all equipment while maintaining precision and consistency

The cost depends on the scope of the project, including the number of production lines, system customizations, and equipment integration. We provide a detailed cost breakdown during the consultation phase, ensuring transparency and value for your investment.

Yes, our system is designed for scalability, allowing you to expand or modify it as production demands grow. This ensures your manufacturing capabilities remain future-proof and adaptable to industry advancements.

You can schedule a consultation or live demo by contacting our team directly. Write us at automation@enwps.com or call on +91 96376 03230 to explore how our automation systems can transform your manufacturing process.

Call Us or Fill the Form

Ready to unlock the full potential of your surfaces? Get in touch with our team to learn more about our Robotic Flaming Treatment System and how it can benefit your business.

-

Contact Number

+91 96376 03230

-

Send us an e-mail

rfq@enwps.com

-

Working Hours

Mon – Fri: 9:00 – 19:00

About ENWPS

ENWPS has a two-decades legacy of providing innovative Automation and Robotics solutions – from concept to implementation, providing quality and comprehensive innovative systems coupled with technology expertise.

Get In Touch

3rd Floor, Godrej Eternia-C, Wakdewadi,

Shivaji Nagar, Pune 411005, India